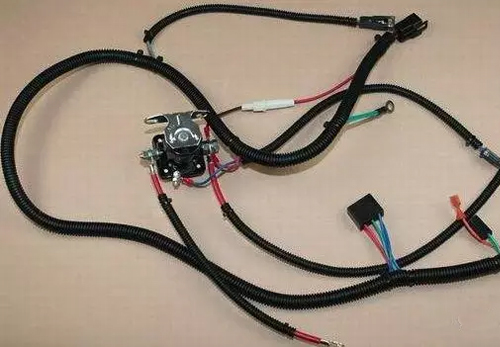

Causes and detection methods of electronic harness failure

In the course of operation, the electronic harness will always fail for a variety of reasons. Common faults include poor connector contact, short circuit between wires, open circuit, grounding, etc.

So, what are the causes of the failure of the electronic harness?

1, natural aging or damage

When the harness is used for a longer period of time, the insulation of the harness begins to crack slowly, and the mechanical strength begins to decrease. Over time, it is easy to cause a short circuit, open circuit, grounding, etc. between the wire and the wire.

2, wire harness terminal oxidation

When the harness terminal is completely oxidized or has been deformed, it may cause poor contact or short circuit of the harness, which may cause the harness to malfunction.

3. Electrical equipment malfunctions

There is also a case where the electrical equipment is overloaded and short-circuited, causing the harness to malfunction.

4, human reasons

The last cause of the malfunction was improper human operation, such as improper wiring harness installation, incorrect wiring of wiring harnesses and electrical equipment, and damage to harness components during maintenance.

Detection and discrimination of electronic harness faults:

Grounding: The law of electronic wire harness burnout is in the circuit of the power supply system, which point is grounded, where the electronic harness is burned, and the intersection of the burnt and the missing part can be grounded for the wire; if the electronic wire harness When it is burnt to the wiring part of an electrical equipment, it indicates that the electrical equipment is faulty.

Short circuit: The wire harness is externally kneaded and impacted, causing damage to the wire insulation inside the wire harness, causing a short circuit between the wires, causing some electrical equipment to lose control and the safety wire to be blown.

When judging, the electronic harness connector at both ends of the electrical equipment and the control switch can be disassembled, and the short circuit of the line can be detected by the electric meter or the test lamp.

Open circuit: Wire breakage failure, except for the obvious cracking appearance, rare faults occur mostly between the wire and the wire terminal. After some wires are broken, the outer insulation layer and the wire terminals are not missing, but the inner core wire and the wire terminal of the wire are broken.

When judging, the tensile strength test can be performed on the high temperature resistant wire and the wire terminal of the suspected open circuit. During the tensile test, if the wire insulation layer is gradually tapered, the wire can be recognized as being broken. Poor line contact, faults occur in the connector.

Poor contact in the connector: When the fault occurs, the electrical equipment will not work properly.

When discriminating, turn on the power of the electrical device, touch or pull the relevant connector of the electrical device, when the connector is touched, the operation of the electrical device is normal, and the abnormality is abnormal, indicating the connector failure.

Pre-sales advice

Pre-sales advice